What are the consequences of noise emissions? The conversion of flow mechanical energy to noise can lead to possible fatigue failure of relief and/or process piping, and potential hearing loss or damage. The costs for additional piping supports and engineering may also increase. Noise can have a negative impact on workers, such as hearing loss, physical and psychological stress, and reduced productivity. Noise can also interfere with plant communication, and contribute to accidents and injuries by making it difficult to hear warning signals.

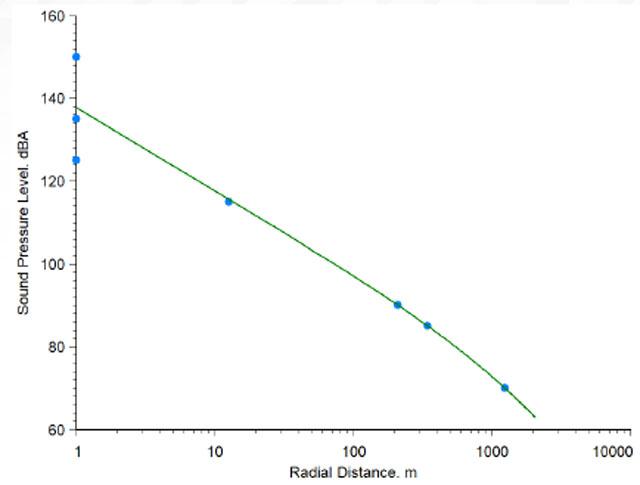

Process Safety Office® SuperChems™ v10.5 users now enjoy enhanced methods for calculating sound power level and sound pressure level (noise):

- Sound power level is calculated for single phase and multiphase flow in complex piping geometries

- Sound pressure level is calculated for single phase and multiphase discharges to atmosphere from process and/relief systems piping

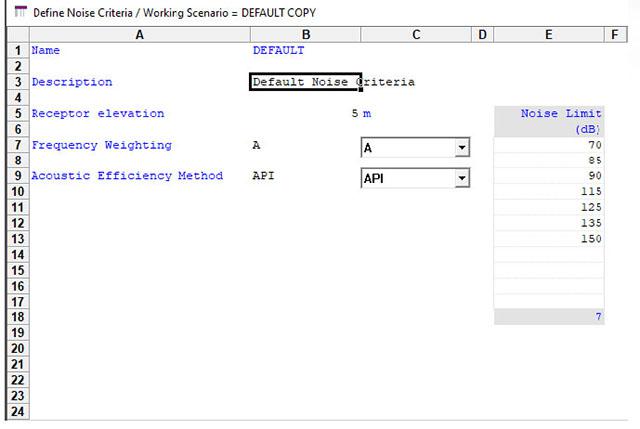

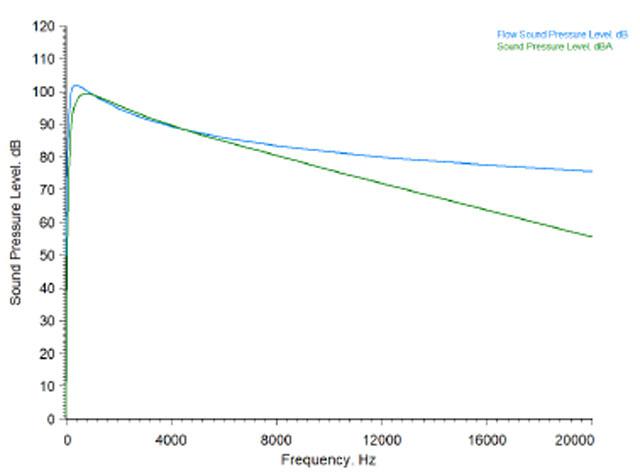

- Multiple sound pressure levels frequency weighting options are available (A, B, C, D)

- Multiple acoustic efficiency methods are available (API, IEC, and ASME)

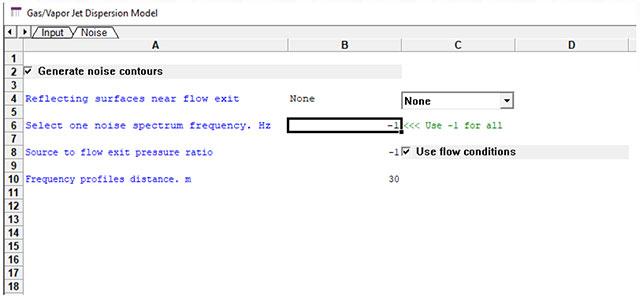

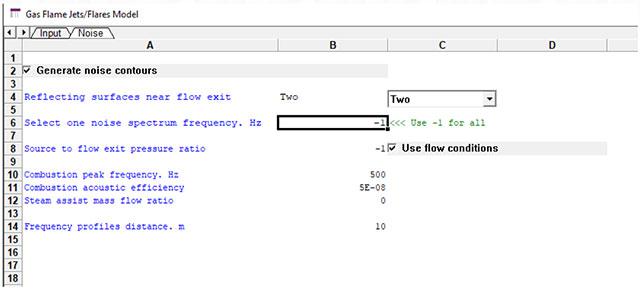

- Sound pressure levels can be calculated at specific frequencies or over the entire frequency range with atmospheric attenuation

Flexible Noise Options Added

The noise definition object adds acoustic efficiency and frequency weighting options to sound pressure level. The A weighting frequency scale is widely used, as it shows the best correlation between sound pressure level and potential hearing damage.

New Enhancements for Jet Noise

SuperChems™ single phase and two-phase jet models include the new enhancements.

New Enhancements for Flame Jet Noise

SuperChems™ single phase and two-phase flame jet models also include the new enhancements.

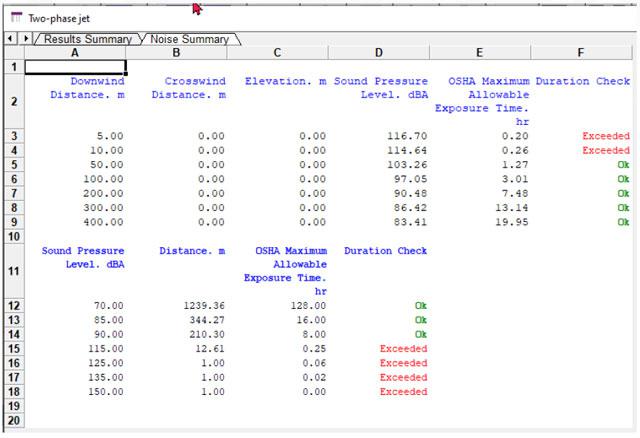

New Reporting Enhancements

A noise summary is added to all the jet and flame jet models with exposure time limits highlighted.

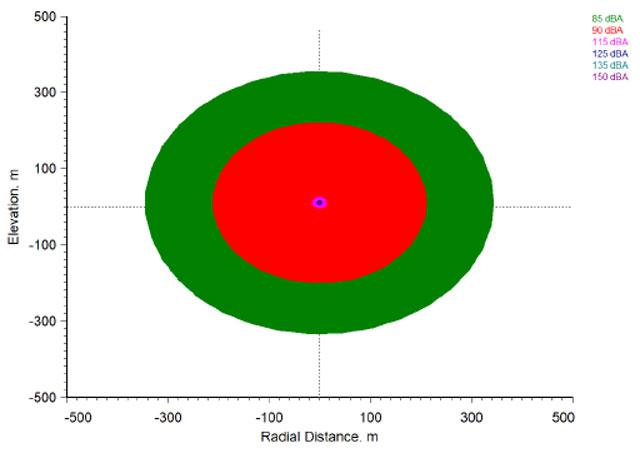

Additional Visual Tools

Noise contours display options are provided for all the jet and flame jet models.

Drill Down into Noise Sources and Attenuation

The noise contours provide multiple displays including vertical profiles, frequency profiles, and attenuation.

Questions?

To ask questions or get help from our highly trained technical support experts, please contact us at 1.844.ioMosaic or submit a ticket to our online support center. We'll be glad to assist.

ioMosaic is committed to leveraging the latest technology to maximize tool performance. Check back often to see the latest information about ioMosaic software and technology solutions.